Proper Handling Instructions For Loading And Unloading

Dec 21, 2023Forklift is a handling tool often used by industrial enterprises when transporting goods. It can effectively improve the efficiency of production and transportation, and promote the improvement of economic benefits of enterprises, whether it is an internal combustion forklift, or an electric forklift, if the wrong operation method is used in the use of forklifts for cargo handling operations; It may lead to goods damage, collapse, and even cause the instability of forklift trucks, resulting in forklift accidents, especially Heavy duty forklift. In order to safely load, unload and transport goods, every forklift driver should fully grasp the correct operation method of cargo loading and unloading.

Operation points of forklift truck during loading and unloading:

1. Stable loading and unloading of goods, control the width of the cargo fork

In order to stabilize the handling of goods, the width of the left and right cargo forks should be roughly controlled at about 2/3 of the width of the pallet.

2. Do not load goods that exceed the allowable load range

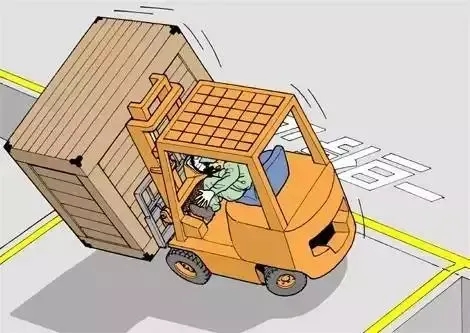

Forklift is based on the front wheel as the fulcrum, the load weight and the balance weight of the tail to maintain balance, if the loading method is not proper, it will become very unstable. If the load exceeds the load table

When the weight is loaded, the balance between the weight and the counterweight is destroyed, and the rear wheel will tilt up, resulting in accidents such as failure to maneuver or tipping over.

3. The loading Angle should be straightened, do not load the goods sideways

When loading the goods, the Angle should be straightened, and the goods will cause the goods to collapse and the forklift to tip over. It should be confirmed that the goods on the pallet are firm and stable, and the stacking is safe.

4. Do not tilt the door frame back and forth when the fork is raised high

In the state of high fork, if the gantry tilt operation is carried out, the vehicle will become unstable, and the goods and pallets are in danger of slipping and collapsing.

5. The cargo fork is loaded, and manned operation can not be carried out in the cargo fork

The fork is used to insert the goods. Do not carry people or lift them on the fork. Otherwise, you may fall or get clipped, which is very dangerous.

6. Staff are not allowed to go under the fork

Regardless of whether the forklift is in working condition, personnel should not go under the fork. If you need to work under the fork, be sure to fix the fork; Prevent falling.

7. When leaving the forklift, the fork must be placed on the ground smoothly

When leaving the forklift, be sure to lower the fork to the ground. Otherwise, the operator may suffer the rubbing of the cargo fork, which is easy to cause injury to personnel.