Hydraulic system noise cause analysis and treatment skills

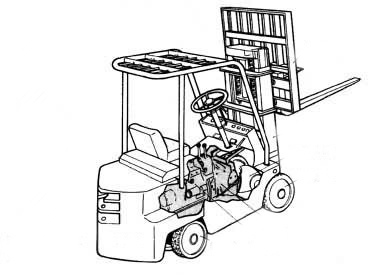

Dec 07, 2023Forklift hydraulic system is an important part of forklift, which is widely used in internal combustion forklift, electric forklift, and material handling equipment. The working device accessories and steering system of the forklift are all driven by the hydraulic system. Therefore, the hydraulic system of forklift directly affects the performance of forklift. The simplest forklift hydraulic system is generally composed of a power source (forklift engine, forklift motor), gear pump, high pressure tubing, multiway valve, lifting hydraulic cylinder, steering hydraulic cylinder and some other forklift control valves. The working principle is that the forklift engine (forklift motor) drives the hydraulic gear pump to continuously produce high pressure oil; The hydraulic oil of forklift truck is sucked out from the oil tank and enters the multi-way valve through the oil pipe. According to different working conditions, the operation handle (controlling the multi-way valve) can be pulled to realize the lifting, landing, forward tilting, backward tilting and steering wheel steering. However, the hydraulic system is also one of the most prone to problems, NEOlift will analyze the hydraulic system noise treatment method.

01 Noise from the piston pump or motor

(1) The suction phenomenon is one of the main reasons for the excessive noise of the hydraulic pump. When the oil is mixed with air, it is easy to form a cavitation phenomenon in its high-pressure area and propagate in the form of pressure waves, causing oil oscillation and resulting in cavitation noise in the system. The main reasons are:

① The oil filter of the hydraulic pump, the oil inlet pipe is blocked or the oil viscosity is too high, which can cause the vacuum degree at the oil inlet of the pump to be too high, so that the air can penetrate.

② Hydraulic pump, pilot pump shaft end oil seal is damaged, or inlet pipe seal is poor, resulting in air entry.

② The oil level of the tank is too low, so that the inlet pipe of the hydraulic pump is directly empty.

When there is high noise in the work of the hydraulic pump, the above parts should be checked first and the problems should be dealt with in time.

(2) Excessive wear of the internal components of the hydraulic pump, such as the wear and strain of the cylinder block and the valve plate of the plunger pump, the plunger and the plunger hole and other mating parts, so that the leakage in the hydraulic pump is serious, and the flow pulsation will be generated when the hydraulic pump outputs high pressure and small flow oil, resulting in higher noise. At this time, the deflection Angle of the variable mechanism of the pilot system can be appropriately increased to improve the influence of internal leakage on the output flow of the pump. The servo valve spool of the hydraulic pump and the piston controlling the flow rate will also pulsate during the moving process due to local wear and strain, resulting in fluctuations in the output flow and pressure of the hydraulic pump, resulting in greater vibration and noise at the pump outlet. At this time, the components with serious wear and strain can be brushed plated or replaced.

(3) The hydraulic pump valve plate is also one of the important components that is easy to cause noise. When the valve plate is in use, due to surface wear or sludge deposition at the opening of the unloading tank, the unloading tank will be shortened and the unloading position will be changed, resulting in oil trapping phenomenon, which will cause higher noise. In the normal repair process, the outlet plate repaired by flat grinding will also have the consequence of short unloading groove, at this time if it is not properly lengthened in time, it will also produce large noise. In the assembly process, the large unloading groove of the valve plate must be installed in the high pressure chamber of the pump, and its sharp Angle direction must be relative to the rotation of the cylinder block, otherwise it will also bring greater noise to the system.

02 Noise of the relief valve

The relief valve is easy to produce high-frequency noise, which is mainly caused by the unstable performance of the pilot valve, that is, the noise caused by the air vibration caused by the high-frequency pressure oscillation in the front chamber of the pilot valve. The main reasons are:

(1) Air is mixed into the oil, forming a cavitation phenomenon in the front chamber of the pilot valve and causing high-frequency noise. At this time, the air should be drained in time and the outside air should be prevented from re-entering.

(2) The needle valve in the process of use due to frequent opening and excessive wear, so that the needle valve cone and the valve seat can not close, resulting in pilot flow instability, pressure fluctuation and noise, this time should be repaired or replaced in time.

(3) The pressure regulating function of the pilot valve is unstable due to the fatigue deformation of the spring, which causes large pressure fluctuations and causes noise, and the spring should be replaced at this time.

03 Noise of hydraulic cylinder

(1) There is air mixed in the oil or the air in the hydraulic cylinder is not completely drained, resulting in cavitation phenomenon under high pressure and causing greater noise. At this time, the air must be drained in time.

(2) The cylinder head oil seal is too tight or the piston rod is bent, and noise will be generated during the movement due to other forces. At this time, replace the oil seal or straighten the piston rod in time.

04 Pipe noise

Excessive dead pipe bending or loose fixing clip can also cause vibration and noise. Therefore, the pipe layout should avoid dead bending as much as possible, and the loose clip must be tightened in time.