A Comprehensive Manual For Electric Pallet Trucks

Sep 11, 2023Electric pallet truck is also known as electric truck stacker or electric truck forklift. It is suitable for heavy load and long time cargo transfer conditions, which can greatly improve the efficiency of cargo handling and reduce labor intensity.

1、 Main Components:

(1) Handle

During the driving process, the electric pallet truck is controlled by the control arm to walk and turn, and the maximum steering Angle of the control arm is 180. The braking function is near the upper or lower end of the manipulator arm, and the power is cut off automatically.

(2) Nameplate

The model number is attached to the nameplate; Rated lifting weight; Maximum lifting height; Be self-respecting; Factory number.

(3) Box Lid

Removable for good visibility during use.

(4) Instrument

Electricity meter, in normal operation, displays the electricity value, reflecting whether the battery power meets the requirements.

(5) Hydraulic Control

The lift and drop handles on the body panel control the lift and drop functions.

(6) Hydraulic Device

Packed in a tank, the pump motor, pump and oil tank are compact.

(7) Power Socket Assembly

When the battery is charging, pull out the socket with the handle and plug it into the plug on the charging machine.

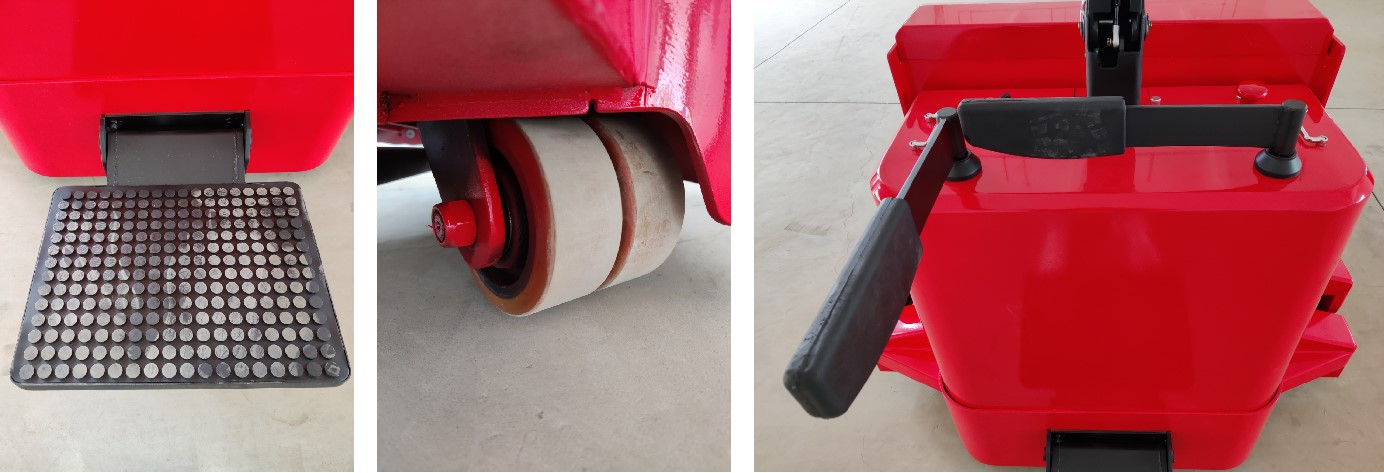

(8) Drive Device With Brake

It is equipped with an electromagnetic electrified brake, a traveling motor, a gear box and a driving wheel, and a steering bearing is arranged between the drive motor and the gear box.

(9) Speed Control Device

Normal operation at 24V voltage, speed controlled by electric control.

(10) Universal Support Wheel

The left and right two universal wheels support to ensure the stability of the car body.

(11) Battery

The battery is fixed in the battery box. The voltage is 24V and the standard capacity is 210Ah.

(12) Pedal

Removable, only power pallet truck operators standing use.

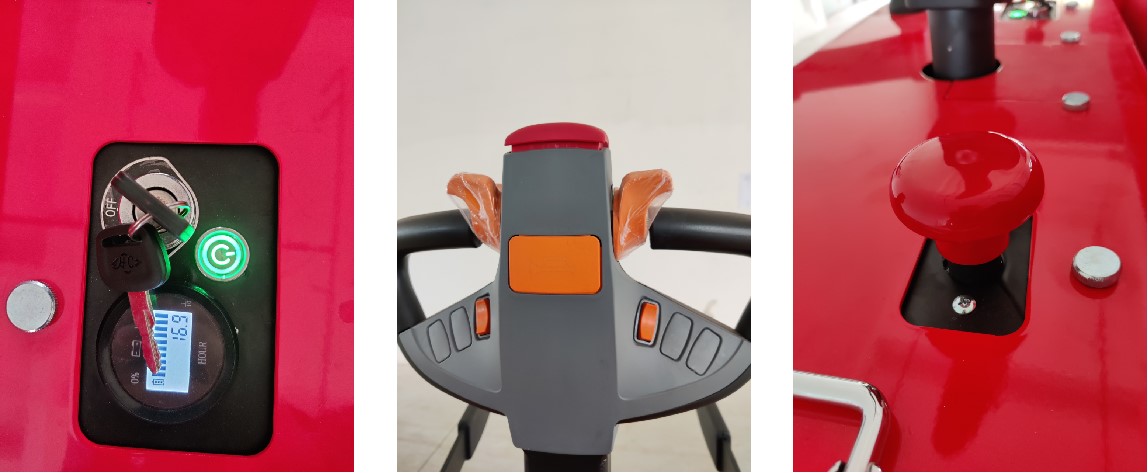

2、Control Device:

(1) Lifting control

Open the key switch and operate the handle in the direction indicated to lift or lower the fork.

(2) Driving direction and speed control

Turn the handle head switch to control the direction of travel, through which speed and acceleration can be adjusted.

(3) Anti-accident safety switch

The operator faces the direction of the fork and the cargo operation, when the direction of the wrong operation backward, the body is too late to avoid, the manipulator arm and the body, the control switch is closed, the electric pallet truck emergency braking. The directional selector switch must be restored to the middle position before continuing.

(4) Horn

Press the horn to sound.

(5) Power socket assembly

Remove the power socket to cut off the power supply in the following cases.

※ Accident

※ In emergency and dangerous situations

※ When welding

When welding around the body, the battery is easily damaged, and the welding current will cause damage if it enters the battery, and the socket must be pulled out.

When charging, pull out the power socket and connect the plug of the charger to the movable socket with the handle. After charging, reset the power socket.

(6) Key switch

This switch function is to control the circuit on and off.

Seven. ammeter

When the key switch is in the open state, the meter displays the battery balance, a total of ten cells, when the leftmost diode exchange flicker, indicating that the battery is insufficient, the battery needs to be charged.

3、Driving Operation:

I. Start

Please proceed in the following order, otherwise the electric pallet truck will not run:

(1) Make sure the power socket is firmly plugged in.

(2) Turn the key switch to the open position.

(3) Ensure that the battery pack has enough power.

Long time low potential operation of electric pallet truck, damage battery life. Do not start the forklift before battery charging is complete.

(4) The manipulator arm is down from the top position and should be between the top and bottom ends

(5) Correctly select the driving direction and control the speed in the ideal state. Slowly accelerate to ideal speed.

Do not operate electric pallet trucks with serious functional defects that endanger safety. Before working every day, you should first check the following safety features:

※ Speaker function is normal.

※ Operating function is intact.

※ Brake function is normal.

※ Hydraulic function is normal.

II. Braking

(1) When the manipulator arm is moved to the top or bottom end, the forklift truck realizes electrified braking.

(2) When the direction switch is turned to the reverse position during normal operation, the electric braking function can be performed. Controlling the running speed can control the power of the traveling electric mechanism.

(3) Parking: Stop the electric pallet truck by releasing the driving direction switch and returning it to the neutral position.

(4) Air gap adjustment: In the case of brake power off, by adjusting the three hollow screws and brake mounting screws, the air gap between the stator and the armature is adjusted to the rated value "Z" with the help of the plug, paying attention to ensure that the air gap in all directions is the same. Then lock the brake mounting screw.

(5) Re-adjustment of the air gap: the rated air gap Z will become larger due to wear. In order to ensure that the brake has sufficient braking torque, the air gap must be re-adjusted before reaching the maximum air gap value. The air gap can be adjusted several times, and when the thickness of the friction brake disc reaches the minimum allowable thickness, the friction brake disc must be replaced. The noise value of the brake is relevant, and in applications requiring very low noise, it is recommended to re-adjust the air gap within the maximum range of the air gap. If the air gap exceeds the maximum air gap value, the pilot brake may not be released, the friction brake disc is burned out, the braking force or the holding force is reduced, and even lead to major accidents. Therefore, it is necessary to check and adjust the air gap, and note that the power supply of the device must be disconnected.

III. Turn

(1) The steering is controlled by the manipulator arm, and the steering Angle can be any position within 90° in the left and right directions.

(2) When the electric pallet truck encounters obstacles, it should not be forced through, and it can turn the control arm to move forward or backward to bypass the obstacles.

Do not allow the wheels to slip.

If the operator's hands or shoes are stained with oil, it is easy to make mistakes and lose control of the forklift, so you should wipe your hands or shoes before driving.

IV. Parking

(1) Release the direction selection switch.

(2) The cargo fork is lowered to the lowest level so that there is no system pressure in the hydraulic system.

(3) Release the control arm and the control arm will automatically return to the parking brake position.

(4) Turn the key switch to the key position.

Unauthorized driving is not allowed.

If you leave, please take the key with you.

4、Operation precautions

(1) Understand the function and use of electric pallet truck. Before use, be sure to read the instruction manual of the device carefully and consult a professional.

(2) Wet ground in rainy days is easy to cause tire sliding, affecting the use of vehicles. In a humid environment, the use of electric pallet trucks should be avoided.

(3) Clean the inside and outside of the vehicle before use, and check whether the power supply and wires are normal.

(4) Operators should wear protective equipment, such as safety shoes, gloves, dust masks, etc.

5、Maintenance precautions

(1) Regularly check whether the batteries and wires of the electric pallet truck are abnormal.

(2) Replace the battery in time according to the requirements of the manual, keep the battery clean and charge in time.

(3) Check the tire pressure of the wheel and maintain the appropriate tire pressure to ensure stable driving.

(4) Regular maintenance of the vehicle, timely replacement of worn or faulty parts.

(5) Store the vehicle in a dry, well-ventilated place to prevent water from wires and appliances.

6、Safety precautions

(1) When using electric pallet trucks, attention should be paid to the smoothness and slope of the road surface to ensure driving safety.

(2) Pay attention to the stability of the goods, and avoid collision or tilt of the goods during handling.

(3) In the process of use, attention should be paid to the situation of other personnel and vehicles to avoid the interaction between personnel limbs and vehicles, as well as possible accidental injuries.

(4) Overload should be avoided when used, and operation should be strictly in accordance with the load requirements of the equipment.

(5) Unauthorized personnel are prohibited from using the equipment.

7、Solutions

(1) Be sure to conduct training and guidance before operation.

(2) Maintain the device regularly to avoid device faults.

(3) Be vigilant during operation, and operate according to the operation manual and relevant regulations.

(4) The goods should be fixed before use to ensure the stability of the goods.

(5) Strengthen management to prevent unauthorized personnel from operating equipment.